The Components of the Waste to Energy Plant

A typical Waste to Energy Plant would contain the following main components:

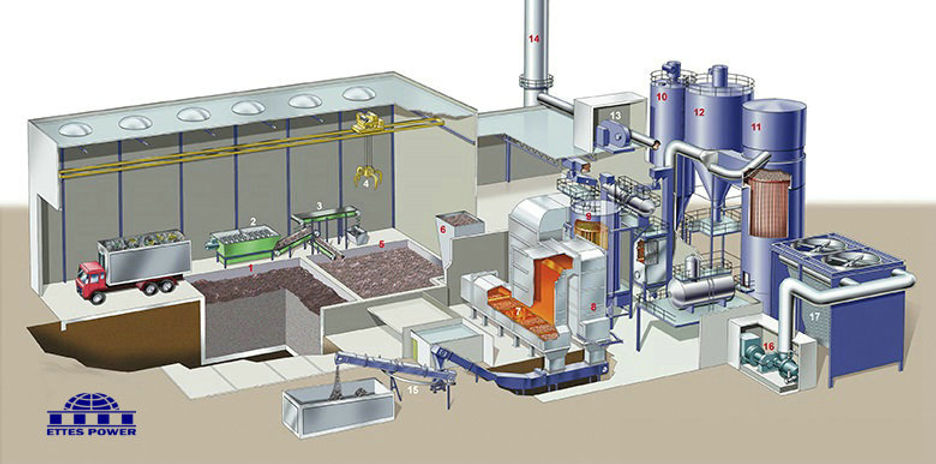

The Tipping Floor & Refuse Bunker:

The tipping floor is the place where the trucks unload the municipal solid waste (MSW) into the refuse bunker. The refuse bunker is divided into separate

regions called cells.

The MSW is stacked vertically in order to conserve cell

space. The new MSW is checked to ensure that large

items such as mattresses, large metal objects, etc.

do not impede combustion in the burner.

Aeration is very important for the reduction of intense

putrid odors in the refuse bunker. The MSW is frequently

moved in order to promote aeration. Induced draft fans

are a necessity to reduce the putrescible odors.

Feed Chute & Hydraulic Ram:

The process of removing the MSW from the refuse bunker

begins with the grapple operator. A grapple

crane operator controls a device, which scoops the

MSW from the refuse bunker and carries it over to the

feed chute. The purpose of the feed chute is to control

the amount and characteristics of the MSW that are

beingfed into the later burner stages. The hydraulic ram

located at the bottom of the feed chute pushes the MSW onto the burner grates.

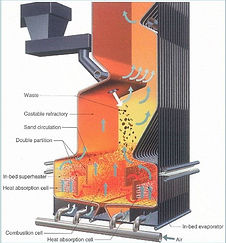

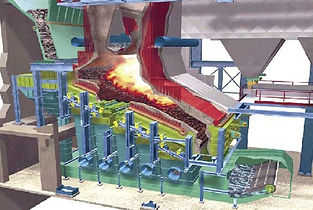

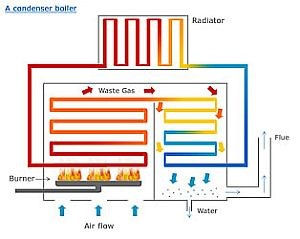

The Combustion Chamber:

Combustion is the process by which a fuel is oxidized by the chain reaction

of radicals, which release heat and convert fuel to products such as ash

and flue gas in a furnace. Combustion is desirable because of a large

reduction in the overall volume of the fuel results. There are three key

elements that are required for combustion: Fuel, Air, and Temperature.

Fuel:

The Fuel for this process is the refuse that enters the burner

via the use of a hydraulic ram pushed onto a stoker grate.

The stoker grate is a series of fixed and moving grate bars

which are sloped downward. The purpose of the stoker

grates is to agitate the MSW to improve combustion. Flue

gas and ash are the products of the combustion process.

The grate is located on a decline to remove the ash that has

settled back onto the grates during combustion. The ash travels as a separate flow path through the plant. The ash volume produced by combustion is three times smaller than the original volume of the MSW. The flue gas then continues to heat the boiler.

Temperature:

The temperature required for combustion is a very important part of the process. The production of pollutants such as NOx, CO is a function of the temperature of the burner. See the section on air pollution control systems for more information regarding the formation and control of these pollutants. The temperature of combustion is dependent on three things, the number of fugitive emissions from the burner, the type of fuel combusted, and the amount of air supplied to the system. Each type of fuel fed varies the amount of heat released from the process. One of the largest concerns of the combustion of MSW is the fact that the fuel feed stream is not homogeneous. The lack of homogeneity requires greater control over the process. A major source of temperature loss from the combustor is the fugitive heat losses due to air pressure leakages, loose flanges etc. Air pressure leakages can also act as a fugitive source of emissions. The amount of air provided to the system can also affect the rate of oxidation of the fuel and therefore the temperature of the burner. The greater the amount of oxygen provided in the fuel the greater the oxidation rate and thus the greater the heat release from the complete oxidation of the fuel.

Air:

The air for the burner is provided by two sources, underfire air, and overfire air. Underfire air is used to control the height of the burner flame. The control of the burner flame height is important to ensure the longevity of the parts located in the combustor. Overfire air is used to prevent the flame from coming into contact with the side walls of the burner.

As noted in the previous section the amount of oxygen provided to the flame can be the limiting concentration that allows for combustion. For most combustion processes, excess air is required.

What is excess air?

Excess air means that the amount of air required for combustion in the actual process exceeds the amount of air, which is predicted theoretically by the stoichiometry of the process.

The percent excess air for the combustion process can be calculated by:

Amount of air actual - Amount of air theoretical

% Excess air = ----------------------------------- (1)

Amount of air theoretical:

It is also important to consider the concentration of the Nitrogen (79 Wt %) in the air. The nitrogen can react with the oxygen to form pollutants such as NO and NO2. This will need to be addressed by the air pollution control equipment later in the process.

Boiler Operation:

One of the advantages of a waste to energy process over a strict

incineration process is the ability to generate electricity. Steam

produced in the boiler is the focal point of electricity generation.

Demineralizer:

The source of the boiler feedwater is the demineralizer unit.

A demineralizer utilizes ion exchange to eliminate hardness ions

(Calcium and Magnesium) and inorganic salts such as NaCl and

NaSO4. The demineralized water must contain little contamination

prior to entering the boiler unit to prevent the formation of silica

and iron oxide vapor in the steam leaving the boiler unit.

The boiler feedwater undergoes heat exchange with the flue gas

stream in the economizer unit.

Deaeration:

The presence of dissolved gases such as oxygen, ammonia and carbon monoxide in the boiler feedwater can cause corrosion in the boiler drum. The concentration of the dissolved gases is directly related to their partial pressure. The greater the

pressure exerted on a gas-liquid system at constant

temperature, the greater is the concentration of dissolved gases

in the liquid. The temperature also can impact

the ability of the gases to dissolve into the liquid. If the

temperature is raised, the concentration of dissolved gases

in the liquid will decrease. At the boiling point, the

dissolved gases will be at their minimum concentration.

This statement is also expressed as Henry’s Law.

Pressure Deaeration is a process, which utilizes both the effect of pressure and temperature on the solubility of dissolved gases. The steam is sent through the boiler feedwater stream to raise the boiler feedwater temperature to within a few degrees of the boiling point. The steam contributes a negligible partial pressure, which at temperatures near the boiler feedwater’s boiling point minimizes the solubility of the dissolved gases. There will be approximately 2% percent dissolved oxygen remaining in the boiler feedwater after deaeration is complete. To further remove the remaining dissolved oxygen chemical oxygen scavengers such as Hydrazine, Volatile Organic Compounds or Sodium Sulfite need to be added to the solution.

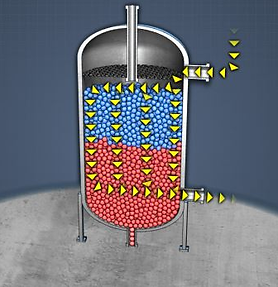

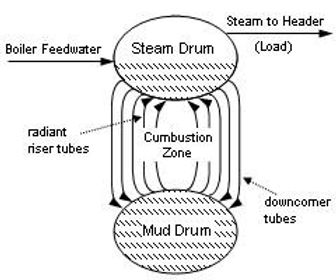

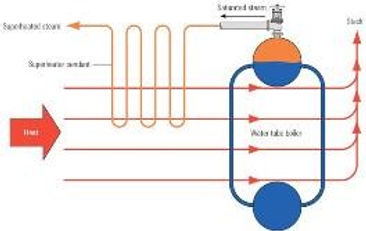

Cycling of Feedwater through the Boiler Drum:

The heated boiler feedwater is carried to the boiler drum by pipes referred to as downcomers. The feedwater is then sent through the boiler drum several times to maximize the amount of steam formed. Pipes referred to as risers carry the liquid/vapor stream back into the boiler drum.

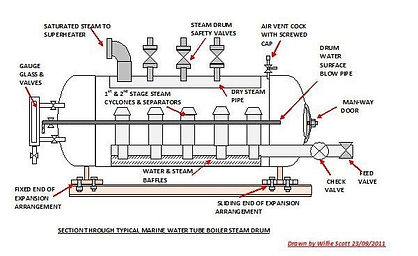

Boiler Drum:

A boiler drum is a unit, which is rated at a certain temperature and pressures to force the boiler feedwater into the vapor phase (steam). As the vapor

phase is formed the liquid level in the drum decreases.

It is important to maintain control of the liquid level in

the boiler drum to prevent damage to the unit.

Complex control schemes have been developed to

control the level of the drum by adjusting the rate of

flow, the inlet temperature, etc. The steam formed in

the boiler drum still contains a certain percent of liquid

content. This liquid contained in the steam is referred

to as the quality. The two-phase system that is formed

(liquid & vapor) in the boiler drum is then cycled through the boiler several times before it is sent to

the superheater unit.

Convection Tubes:

The convection tubes are where the cooler water being fed to the boiler drum and the liquid/steam mixture exiting the boiler drum exchange heat in order to

further raise the temperature of the boiler feedwater. The heat

exchange between the liquid feedwater stream and the liquid

/steam exit stream occurs through the use of a fluid as the

medium of heat transfer. This type of heat transfer is referred

to as convection.

Mud Drum:

The Mud drum is a unit, which is located beneath the boiler drum to collect the solid materials, which precipitate out of the boiler feedwater due to the high

pressure and temperature conditions of the boiler. The process

by which suspended solids are collected in the boiler is

referred to as cycling. Cycling occurs because the boiler

feedwater is sent throughout the boiler drum a number of

times. This is done to produce the maximum amount of steam

per unit volume of feedwater. On each run through the boiler

drum, a portion of the boiler feedwater is vaporized. This

results in an increase in the solids concentration in the boiler

drum. Eventually, the solids concentration hinders the ability

to maintain steam generation efficiency. At this time, a stream

of compressed air is used to blow the solids into the mud drum beneath the boiler. The mud drum, then stores these materials for later disposal. This process of using compressed air to remove the collected suspended solids is referred to as blowdown.

Chelating & Dispersing Agents:

Chelants such as EDTA and NTA are molecules, which have sites to form complexes. They are generally weakly acidic in nature. Chelants are particularly useful

because the complexes that they form are water-soluble. This

allows suspended solids contained in the feedwater to be

solubilized or contained in the solution. This reduces the amount

of cycling in the boiler and increases the period of operation

between blowdown. Chelating agents are used for treating

iron oxide and additional hardness ions that are found in the

boiler feedwater stream. These ions are present due to the water

added to the boiler feedwater stream to maintain the level of the

boiler drum. This water is called the makeup water. The Chelan is

added the feedwater side of the pump discharge line. This is

done in order to form the complex prior to the entrance of the

boiler drum. Control must be maintained over the Chelants feed stream in order to prevent the Chelants from complexing with the magnetite film formed on the boiler drum. This film acts as a protective layer to the boiler unit surface. Unfortunately, the Chelants may not complex all of the suspended solids in the boiler drum. A dispersing agent needs to be added to prevent any additional particles that remain un-complexed from growing larger. Dispersants are anionic polymers, which impede the crystal formation of the suspended solids. Dispersants act on surface-to-surface and particle-to-particle attractions, which are the primary mechanism for the agglomeration of suspended solids in the boiler drum.

Activated PO4 Treatment:

Adding phosphate (PO4-) to the boiler drum is another method of treating suspended solids in the boiler feedwater stream.

The activated PO4 treatment

results in the formation of insoluble

precipitates in the boiler drum.

Unlike the chelation treatment, this

process is carried out solely in the

boiler drum. The goal of the

treatment is to precipitate calcium

and hardness ions in the phosphate

form. The PO4 is particularly

effective for the treatment of iron

deposits on boiler surfaces. These deposits act as miniature boilers taking liquid from the feedwater and producing steam. During this process, iron deposits act to hold caustics and suspended solids within the deposit. This causes depositional growth on the surface of the boiler. PO4 acts to remove the deposits and buffer the pH when the caustic is released. In order to control the size of the precipitate that is formed, Dispersing agents are used to controlling the particle size of the precipitate. Dispersants interfere with the crystal complex of the suspended solid.

An activated PO4 treatment is not as effective as chelation for treating magnesium hardness. Magnesium Phosphate formed by this process adheres to the surface of the boiler and reduces its effectiveness

Economizer:

An economizer is a heat exchanger, which acts to preheat the boiler feedwater by transferring heat from the flue gas stream. The flue gas stream contains excess

heat from the combustion process.

Why the heat exchanger is called an economizer?

The heat exchanger is referred to as an economizer because

for every 40 degrees Fahrenheit, which the flue gas

temperature is decreased, there is a one percent increase in

the thermal efficiency of the plant. As the thermal efficiency of

the plant increases, the plant saves money by utilizing the heat

from an existing source instead of requiring heat from another

external source.

Superheater:

The steam that is produced in the boiler has a certain percentage of moisture content. This moisture content is referred to as the quality of the steam. Due to the

high velocities of the steam inside a turbine, the moisture

content of the steam can shear the turbine blades. A

superheater is utilized to remove the moisture content in

the steam. Raising the temperature above while keeping the

pressure constant does this. Steam, which undergoes this

process, is referred to as superheated steam. The degrees of

superheat are a term, which is used, describes the

temperature difference between the raised temperature and

the temperature at constant pressure. Let’s clarify this further by giving an example.

Example of Degrees of Superheat:

T=350 C, P=8 atm

T=612 C, P=8 atm

Degrees of Superheat=612-350=272 C

Steam Turbine:

A turbine is a device, which generates a network by passing a fluid, such as steam, through a series of rotating blades. The blades are

perpendicular to the flow direction of

the steam. The steam expands in the

turbine due to the pressures below

atmospheric created by a condenser

attached to the turbine. The expansion

of the steam results in the rotation of

the turbine blades. The rotating

blades are attached to a shaft.

This shaft does mechanical work on

the A/C windings of the electrical

generator.

Electric Generator:

The Electrical Generator contains three A/C windings, which are spaced 120 degrees apart. These windings consist of a magnet, which is

encased, in the wire. The magnet

creates a magnetic field. The work

done by the blades on the windings

results in a motion, which is

perpendicular to the magnetic field. A

current is generated due to this motion

in a direction, which predicted by the

right-hand rule. The right-hand rule

states that this direction is

perpendicular to both the motion of

the windings and the magnetic field.

The wires on the A/C windings have a

resistance associated with them. The voltage drop produced by the A/C windings is dependent on the product of the current and the resistance. This statement is defined as Ohm’s Law.

Condenser:

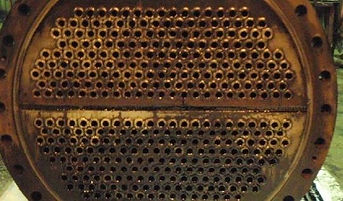

The condenser is a device, which is used to convert the steam back to the liquid phase. A multiple pass shell and tube heat exchanger is used to maximize the

amount of heat transfer with water from the cooling tower.

The water circulated from the cooling tower returns to the cooling

tower to be atmospherically cooled. The liquid formed from the

steam, the condensate is then recycled back to the back into the

boiler feedwater stream. It should be noted that during the

condensation process a number of gases become dissolved in the

condensate. These dissolved gases are treated by the deaerator.

Air Pollution Control Systems:

WTE facilities are one of the largest emitters of sulfur and nitrogen oxides and carbon monoxide. Due to the combustion process, there is an enormous number of

particulates, or fly ash, produced and emitted from the

combustion zone of the incinerator. Hydrochloric acid,

dioxin/furans, cadmium, lead, and mercury are also emitted due

to the random and sometimes unknown composition of the fuel

stream. In order to reduce these emissions and comply with

federal regulations, air pollution control devices are a necessity.

Particulater:

The outlet gas stream of a WTE is full of fly ash, carbonaceous material that is a result of poor combustion practices. Ideally, particulates should be minimized to

almost none, but the fuel stream of a WTE is such that particulates will

be produced. Fortunately, it is against the law to emit tons of fly ash

directly into the atmosphere. For this reason, particulate removal

systems were designed, built and put into operation. The most common

particulate removal systems are bag filters and electrostatic precipitators

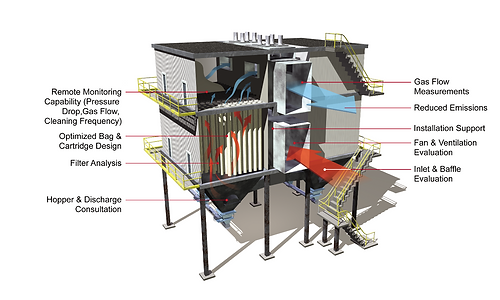

The Baghouse:

A Baghouse is basically a large box with forty to one hundred 6” diameter and 12-foot long bags located inside it for the effective removal of

particulates from .01 micrometers to

100 micrometers in diameter. They are

situated vertically, and the dirty flue gas

enters through one side of the house near

the bottom and exits the other side near the

top, with 99% of the particulates removed.

The bag filters nominally use a woven fabric

for collection. The collection process is not

merely a screening or a filtration of the dust

since the openings in the cloth are many

times the size of the dust particles collected.

The efficiency of a new bag may be low for a few moments until it develops a precoat of dust that serves as the filtering layer. Once precoated, the bag usually retains sufficient solids in its pores so that it does not return to its original efficiency.

The filtration process becomes inefficient after the bags have been saturated. It is at this moment that a control system will engage a cleaning mechanism. Popular cleaning mechanisms are through shaking or high-pressured air. The former method simply shakes the particulates of the bags, which fall into a hopper at the bottom of the baghouse. The latter method utilizes high-pressured air injected at the top of the baghouse to spray the particulates off the bags and into the hopper. The only downfall to the shaking method is higher ware on the bags and possible tearing.

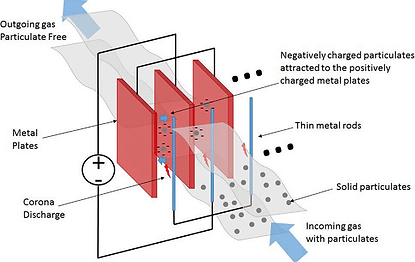

Electrostatic Precipitator:

The Electrostatic Precipitator, or ESP as it is affectionately called, is also a large box. However, it contains long metal plates, upon which particulates are

collected. The collection is based on imparting a

charge to particles in an electric field, which then

causes them to migrate and deposit on a collection

plate of the opposite charge. Liquids agglomerate on

the collection plate and drain off, but solids must be

removed by rapping, which is similar to shaking.

When power is applied to a preceptor, no current flows

until a sufficient voltage is achieved to create a corona

discharge (gas ionization) at the discharge electrodes.

Then particle charging, and deposition begins. As the

voltage is increased further, the field strength becomes more intense and precipitator efficiency increases until the point where spark-over or arcing from the discharge electrode to the collecting plate occurs.

For maximum collection efficiency, the voltage should be maintained just short of spark over. Unfortunately, spark over potential is an operating variable affectedly changes in temperature; dust resistively, moisture content, and frequency and efficiency of removal of collected dust. For maximum operability, the difference in potential between the start of corona and spark over should be as large as possible. This difference decreases as gas temperature increases or system absolute pressure decreases. The difference is greater for negative-polarity current than for positive. Because of this, most WTE ESP’s are run with negative polarity.

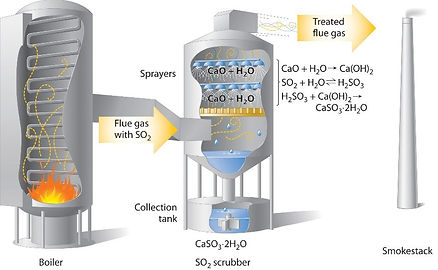

Lime Scrubbing:

Nitrogen Oxides, Sulfur Oxides, as well as various other pollutants can be successfully “scrubbed” out of the flue gas stream using a process

called Lime Scrubbing. Lime, CaCO3, is a

neutralizing agent, which reacts with the acid

gasses in the gas stream. The products of the

reaction are calcium salts and can be used in

cement manufacturing. The lime scrubbing process

takes place in a reaction chamber, usually 25 feet in

length and 5 feet in diameter. The reaction chamber

provides reaction time for complete conversion of

the acid gasses with the lime. There are several

methods of Lime Scrubbing and they can be

incorporated before or after the particulate removal device.

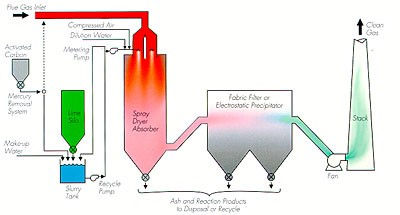

Spray Dryer or Semi-Dry System:

Lime is delivered in a slurry form that is mixed with water, to a reaction chamber where it is atomized into fine droplets. These droplets evaporate into the

reaction chamber and the reagent reacts with the

acid gas in the wet form at the boundary of the

droplet and continues to react in the dry state after it

exits the reaction chamber. The acids are converted to

dry salts that are filtered, along with the ash and toxic

materials.

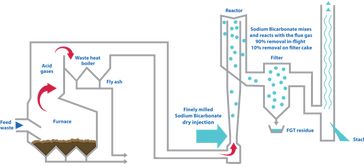

Dry Injection or Dry-Dry System:

Lime is injected in a dry state before the baghouse and

reacts with the acids as it is airborne and as part of the

filter cake on the bags. All the solids are removed, as

described in the Baghouse/ESP sections.

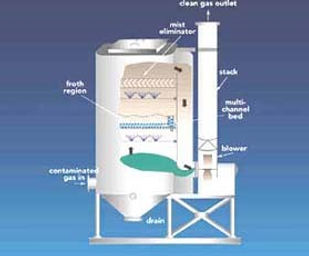

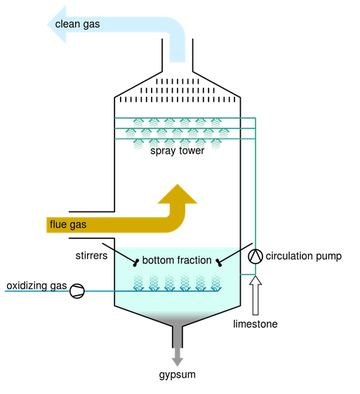

Dry-Wet System:

In some cases, a wet scrubber is used after the baghouse to either improve the acid gas scrubbing, perform all of the acid scrubbings, and/or improve the

condensation and removal of gaseous toxic materials.

This wet scrubber can be added to either of the above dry

scrubber arrangements or can be used without any previous

acid gas scrubbing. 9.5 Induced Draft Fan.

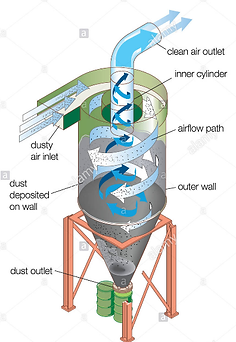

An essential part of the air pollution control system is the

Induced Draft Fan. It is located between the air pollution

control units and the stack. It is necessary for proper flow

through the system. The flow must be fast enough to keep

particulates from settling out in the ductwork, as well as

strong enough to overcome the pressure drops across all

control equipment. Fans can beeither centrifugal or axial

type. The shape of the vanes on the fan characterizes them.

The fan vane shapes improve efficiency and ease of

maintenance depending on the type of gas stream it is

handling.

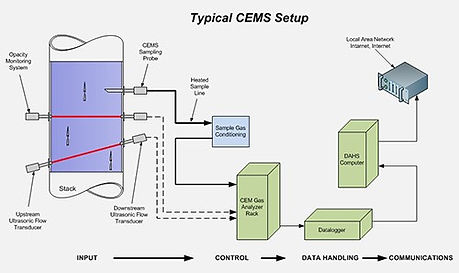

Continuous Emissions Monitoring System aka CEMS:

More importantly than anything else in an air pollution control system is its monitoring system. It can be said that an APC system is only as good as its CEMS. For we must know exactly what is coming out of our stack in order to keep good control. CEM systems are located before the stack and measure a number or parameters:

PM - Particulate Matter less than 10 micrometers

SO2

HCl

NOx

CO

Dioxin/Furan

Cadmium, Lead, Mercury

Opacity - visibility of the plume gas

The CEM system consists of several pieces. First, a sample of gas is extracted from the ductwork or stack using a probe. The probe samples continuously, hence the name. The sample is then sent, through piping, to analyzers located within the plant. Prior to analysis, the gas is put through a filter to remove all moisture. Then, using spectral and refractive methods, the concentration of a pollutant is determined. The major drawback to this is the enormous amounts of data that is now being generated. For this, several computers are attached to the analyzers and compile the data. There are many software companies selling programs to compile the data and then give the user the ability to manipulate the data to generate reports, tables, charts, and most anything the user has in mind. The programs are usually very flexible and anyone with a logical thought process can generate their own personalized reports

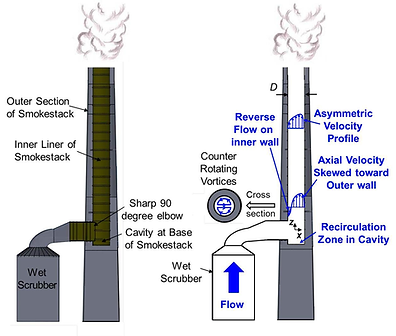

Emission Stack:

The final element of an air pollution control system is the stack. The main reason it is part of the control system is that of the dispersion factor.

The natural atmosphere has the ability to cleanse itself

throughdispersion of particulates and gases

throughout its vast volume. Unfortunately, man has

added more pollutants than the atmosphere can

handle. Due to this fact, stacks must be made high

enough to disperse the limited pollutants into the

atmosphere. The GEP, or general engineering practice,

for obtaining stack height is governed by this equation:

Hs = 2.5 * Hb

Essentially, build the stack 2.5 times as high as the

tallest building in the plant.

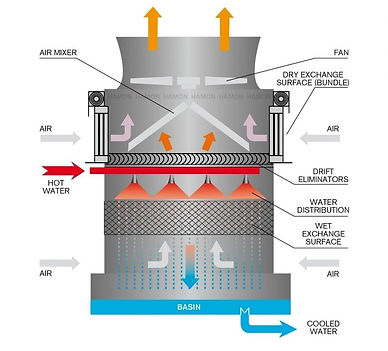

Cooling Tower:

The cooling tower is a structure used to cool the water, which is sent to the condenser to perform heat exchange with the steam exiting from the turbine.

Two of the more common methods for cooling are

direct air contact and fan cooling. Indirect air contact,

the cooling water is stored and the temperature

gradient between the cooling fluid from the

condenser and the ambient air is sufficient to produce

heat transfer to the atmosphere. Cooling towers

designed for small pipes containing the heated fluid

from the condenser characterize fan cooling. Large

radial fans blow air across these pipes. This produces

sufficient temperature gradients for heat transfer with

the air.