The Solution

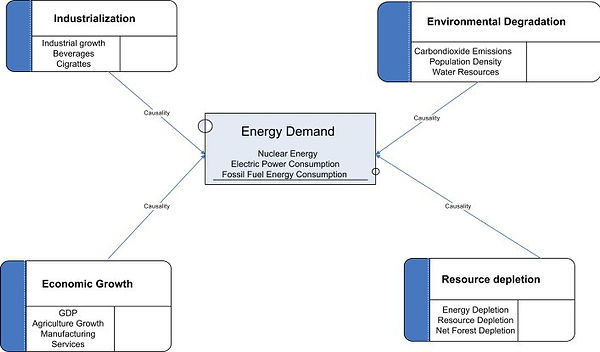

It’s an old story. A rich country’s aid agency pours millions into a new industry in a poor country, in the hope of boosting its economy, but it never really works. The factory keeps getting shut down by blackouts or lack of spare parts. Raw materials don’t arrive; workers get sick; engineers emigrate. There is a caring and high-minded class that genuinely wants to help with the heartiest inspiration to improve the lives of the impoverished nations. As discussed in the previous chapter, economic and historical research has overwhelmingly shown that industrialization is linked to rising educations, longer life spans, growing individual and national income, improved overall quality of life and health. It is a common knowledge that any kind of industrialization would involve increasing energy demand, as industrialization requires a force to run the machines, and electricity is that driving force behind the development of a country, and its effort to eradicate poverty. So, is there a one in all solution? The proper disposal of garbage, no environment or health issue, industrialization and elimination of poverty. We need cheap power, and the source of raw material lies within our reach for a mere cost.

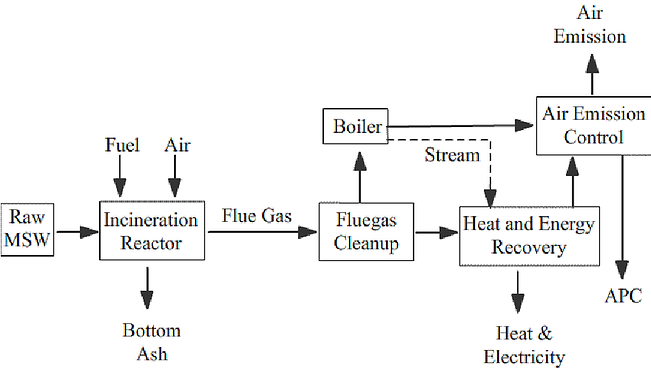

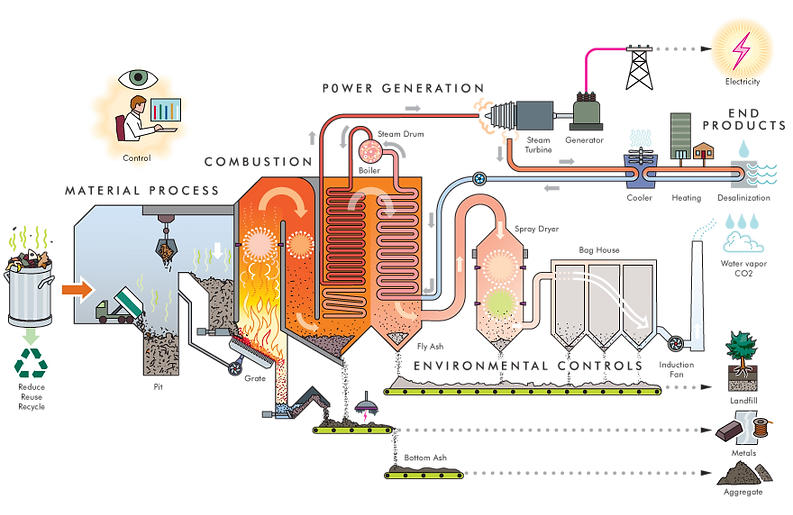

The goal of moving towards a sustainable society means that in all aspects of our daily lives we must strive to diverge from our current linear outlook on major natural resources. Linear, in this context, is referring to our use of resources; materials are extracted from the earth, manipulated and intermingled into a useful product and then disposed of into what we have been treating as a bottomless storage pit. Electricity is most often generated at a power station by electromechanical devices, called generators. The generators are primarily driven by heat engines fueled either by combustion or nuclear fission but also by other means such as the kinetic energy of flowing water and wind. Other energy sources include solar photovoltaics and geothermal power. In all of these modes of power generation expensive fossil fuel, or higher value resources are needed, but many times we forget a very inexpensive form of raw material, and that is the millions of tons of garbage. Use of MSW as fuel not only saves huge spaces of land, but the reduction of volume is more than 90% and above all its free. Electricity from Municipal Solid Waste. Energy recovery from waste is the conversion of non-recyclable waste materials into useable heat, electricity, or fuel through a variety of processes, including combustion, gasification, pyrolization, anaerobic digestion, and landfill gas (LFG)recovery. This process is often called waste-to-energy (WTE). Electricity can be produced by burning "Municipal Solid Waste" (MSW) as a fuel. MSW power plants, also called waste to energy (WTE) plants, are designed to dispose of MSW and to produce electricity as a byproduct of the incinerator operation. A flow diagram of a WTE plant shows the process of the conversion of the MSW to power.

Flow Process of a Waste to Energy Facility

Schematic of a WTE Facility

Benefits of Waste to Energy

Compared to Landfilling waste incineration, Waste-to-Energy facilities offer several advantages:

1. Resource savings and recovery greatly expanded.

Producing steam at the Huntsville Waste to Energy facility alone saves over 200,000 barrels of oil being used each year. Metals left in the municipal solid waste stream can be extracted from the ash resulting from incineration and the metals can be recycled.

2. Waste to Energy facilities generates power in the form of electricity or steam.

The Huntsville Waste to Energy facility in Texas can deliver up to 400,000 lbs/hour of uninterruptible steam to the U. S. Army’s Redstone Arsenal. Efforts are being made to assist Redstone in becoming “Energy Independent.” Using on-site energy sources would enhance Redstone’s energy security.

3. Waste to Energy is a Net Greenhouse Gas Reducer.

Methane is a greenhouse gas, which is mostly emitted from decomposing waste in landfills. It has more than 25 times the potency of carbon dioxide and is ranked as a dangerous contributor to climate change. Waste to energy facilities avoid the production of methane while producing almost ten times more electricity from each ton of waste compared to landfills. And, waste to energy facilities is the only solid waste disposal option with state-of-the-art air pollution control technology.

4. WTE facilities in the US account for approximately 20% of all renewable electricity generation.

WTE facilities, unlike wind and solar, are capable of providing baseload renewable electrical power (baseload meaning 24/7 availability).

5. Landfill usage and landfill expansions greatly reduced.

Waste to energy facilities typically reduces waste volumes by 90%. Fewer and smaller landfills are needed to process ash, and this protects a valuable natural resource – our World.

6. Trucking of waste long distances can be greatly reduced.

With a waste to energy facility in a community, shorter trucking distances result in less air pollution, less truck traffic. Large regional landfills are often located long distances from the communities using them.

7. Tipping fees remain in the community where the waste is generated.

Large regional landfills are usually privately owned, and their revenues often do not remain in the communities generating the waste but, waste to energy facility revenues largely remain in the community. Tipping fees at regional landfills are based on levels of competition from other regional landfills and may not be related to the cost of disposal. Because of long-term contracts and a fixed debt repayment structure, waste to energy facilities offer stable tipping fees for municipal waste. Large regional landfills, usually privately owned, compete with other landfills for waste and the tipping fees can be unpredictable.

8. The economy of the community is enhanced.

According to the Energy Recovery Council, the average waste to energy facility is responsible for the creation of 100 full-time jobs. Generally, these are salaried, skilled positions with relatively high pay. And, these jobs have at least a 40-year projected life.

In a nutshell, Waste-to-Energy facilities offer several advantages:

•Resource savings and recovery greatly expanded

•Typical savings from a WTE plant: 200,000 barrels of oil

•Waste to Energy facilities generate power in the form of electricity or steam (400,000 lbs. of steam)

•Waste to Energy is a Net Greenhouse Gas Reducer

•WTE facilities: Solid waste disposal option with state-of-the-art air pollution control technology

•WTE facilities in the US account for approximately 20% of all renewable electricity generation

WTE capable of providing baseload renewable electrical power (baseload meaning 24/7 availability)